Description

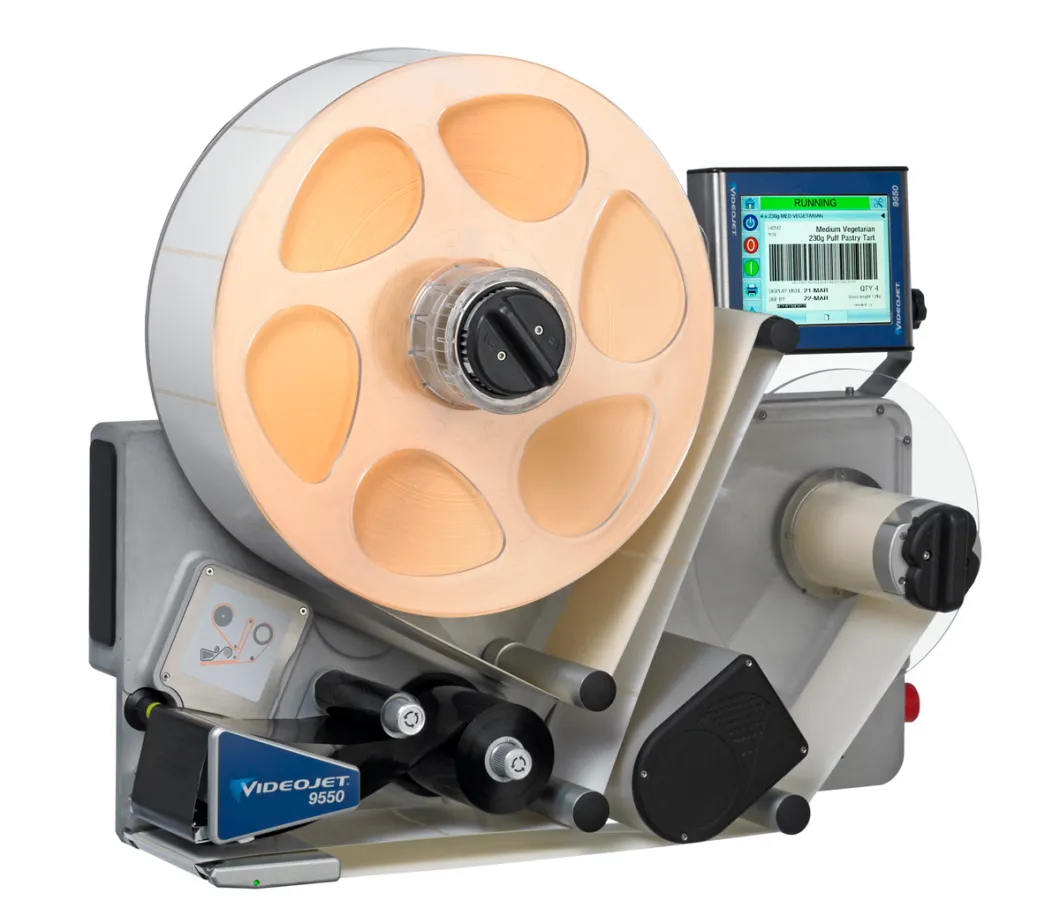

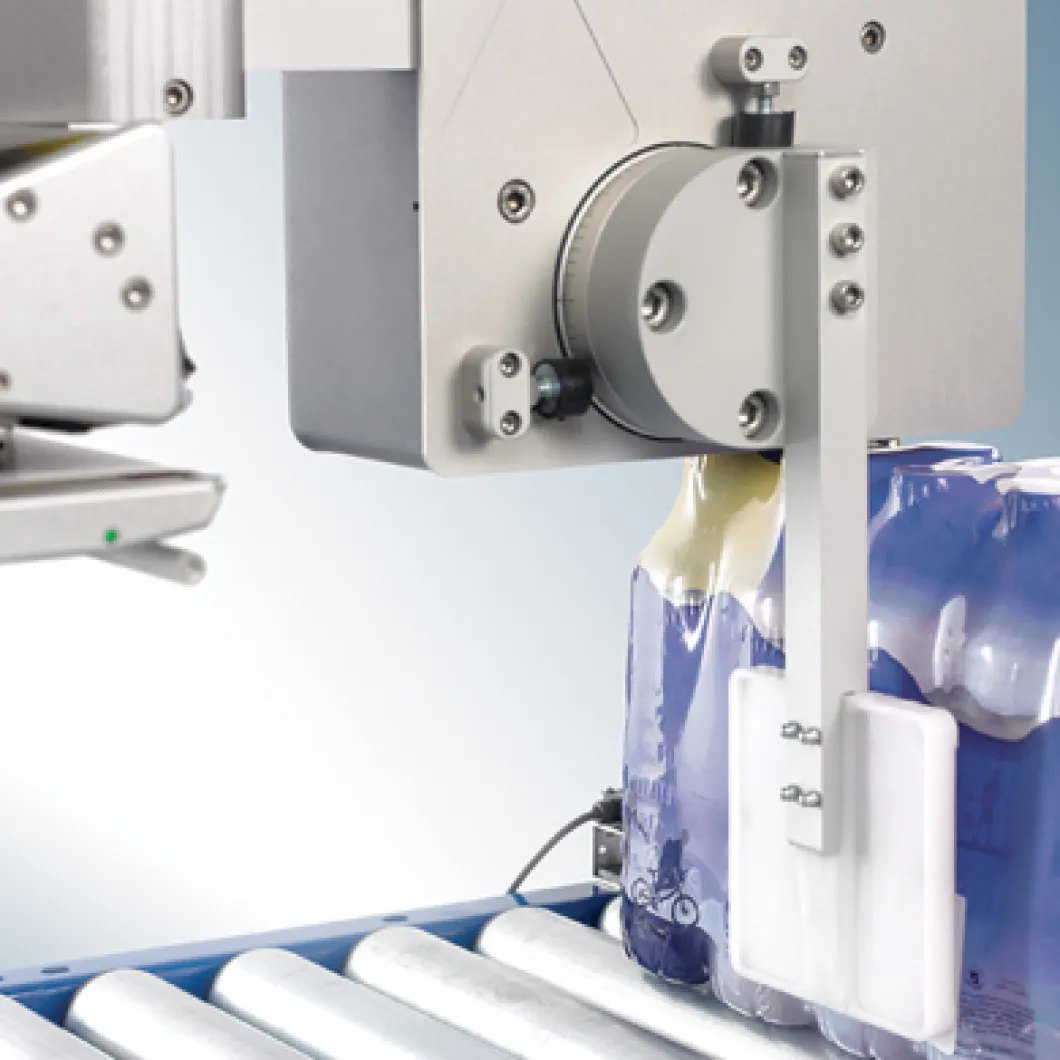

Print and Apply Labeler

Labeling and Label Applicator Machine

The 9550 label printer with Intelligent MotionTM is a smarter print and apply labeling machine that targets zero unscheduled downtime and reduces costs and errors in case coding operations. Automatic, precise control of the entire system together with Direct Apply label placement, provides the most efficient and reliable labeling.

Reviews

There are no reviews yet.